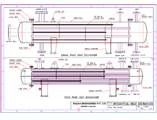

Shell and Tube Heat Exchanger

Heat Exchangers are designed and manufactured to facilitate indirect heat transfer between the two fluids. The two fluids can be liquid and liquid or vapor and liquid. The shell-and-tube heat exchanger has two main areas – Tube side and Shell side

Kalina Engineering is a proven Shell and Tube Heat Exchanger manufacturer.

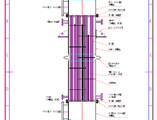

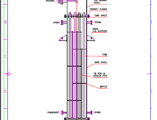

Construction and Manufacturing of Shell and Tube Exchanger-

Main components of Shell and Tube type heat exchanger are- Shell, Tube, Tube sheet, Baffles, Tie roads spacers and Channel.

Shell

The cylindrical shell can be fabricated from rolled plate or from pipes.

Tubes

Tubes can be plain tubes. Or heat transfer surface area of the tubes can be increased many folds by using finned tubes or corrugated tubes. Shell tube heat exchanger with fin tubes are known as finned type heat exchanger and with corrugated tubes it is known as corrugated tube heat exchanger.

Tubes of heat exchangers are sourced from the reputed manufacturer.

Tube sheet

Tubes of the heat exchanger will be held on both the sides by Tube sheets. Tubes will be inserted through holes provided on tube sheets. Tubes are firmly fitted in the tube sheet either by welding or by mechanical or hydraulic expansion.

Baffles

Baffles are provided to support the tubes, to maintain the space between the tubes and it also channelized the fluid flow as per design through the shell side of heat exchanger.

Tie Rods and Spacers

Tie rods and spacers will hold the baffle assembly together; and will also maintain the spacing between the baffles. One end of the tie rods are secured to the tube sheet and other ends are secure in the last baffle.

Channels (Heads)

Channels or heads are provided for shell-and-tube heat exchangers to contain the tube side fluid and to provide the desired flow path.

Application of Shell and Tube Exchanger

Shell and tube heat exchangers are used as condensers, reboilers, process heaters, coolers and falling film evaporator.

Benefits of Kalina Engineering Shell and Tube Heat Exchangers

- Adheres to TEMA, ASME and other standards with special attention to Argon and Arc welding procedures

- Also offered with fin tube or corrugated tubes. As these design offered higher heat transfer area.

- Offered in Carbon Steel, Stainless steel, Copper tubes

- Manufactured as per your exact specifications

- Manufacturing facilities approved by the renowned consultants and Third party inspection agencies

- Third party inspection offered. Test certificates as per your requirement will be provided

- Value added supply of automation, valves, pipes and fittings with process equipments

Web Sales Agency

Web Sales Agency