Distillation Equipment Manufacturer

Distillation is a process of separating component substances (fractions) from the whole (liquid mixtures) through vaporization and condensation. As substances (fractions) of liquid to be distilled have different temperate for vaporization, a system should be designed to facilitate vaporization, condensation and removal of the various condensates. Process removes fractions of whole and it is specifically known as fractional distillation.

Benefits of distillation equipment manufactured by Kalina Engineering

- We manufacture complete distillation system or individual equipment for distillation process

- All equipment available in Carbon steel or Stainless steel

- Manufactured as per your drawings and specifications

- Strident quality assurance system

- Manufactured as per ASME

- Reliable and proven. With more than 30 years of experience

- Complete supply of Pipes and Valves for the plant

- Choice of buying Automation components of the renowned brands

- Assistance in installing the system

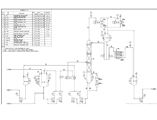

Distillation System Description

Configuration of distillation system will depends on feed ( liquid to be distilled ) and desired products (condensate). We will customize the distillation system as per your requirements.

A typical distillation system will have following equipment

Kettle reboiler-Distillation column- Main condenser and Product cooler

All equipments are also offered individually or as a system. It can be part of Alcohol distillation system or solvent recovery system or complete system for Alcohol, Ethanol distillation or we can also manufacture distillation system for your proprietary distillation process.

Brief Description of individual equipments of distillation system manufactured by Kalina Engineering

1. Kettle Reboiler –

Distillation is the process of collecting vaporizing vapor by condensation process. Kettle reboiler will create the vapor of liquid to be distilled. Kattle reboiler will have U tube bundle inserted into the cattle. Heating media will be circulated through the tube bundle, which in turn will transfer the heat to the liquid inside the kettle.

2. Distillation Column –

Distillation column is the heart of distillation system. Vapor created in kettle reboiler will be condensed in the distillation column. Fractional distillation column will separate the components (fractions) by repeated vaporization-condensation cycles within distillation column. We offer packed as well as non-structured column. Read to know more…

3. Condenser –

Liquid to be distilled will be partially condensed in the distillation column and remaining uncondensed vapor will be condensed in the condenser. It is shell and tube condenser with vapor in the shell and water in the tubes.

The system can also have accessories and supporting equipments like Vent condenser, Reflux drum, product cooler and a return line as per process requirement.

Vent Condenser

From the condenser, partially condensed vapor will further condensed in the vent condenser.

Reflux Drum

Part of Condensate collected from the condenser will be collected in the reflux drum. And will be returned to the upper part of the distillation column. Inside the column, the down flowing reflux liquid provides cooling and condensation of the up flowing vapors thereby increasing the efficiency of the distillation tower.

Product Cooler

If your product needs to be further cooled after receiving from the condenser, we can be offer Product Cooler.

Product Receiver

Condensed, final products will be collected in the product receivers. As per your requirements we can manufactured the product receiver.

Web Sales Agency

Web Sales Agency