Jacketed Vessel Manufacturer

During Exothermic reaction heat will be released by reactants and during Endothermic reaction heat will be absorbed. In both the processes temperature should be controlled as per process requirements for the perfect result. A jacketed vessel will facilitate the above.

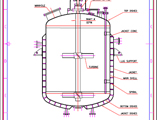

Jacketed reactor has a jacket surrounding the main vessel. During reaction, temperature of reactants is controlled by circulating heating or cooling media through the jacket. Ideally suitable for the heating below 150 Centigrade (302 Fahrenheit). Commonly used heat transfer media include water, steam, hot oil such as Therminol™, and Dowtherm A.

Kalina Engineering is a proven jacketed vessel manufacturer. Jacketed vessel can also be offered in Dimple design .

Benefits of Kalina Engineering Jacketed Vessel

- Available in the range of 500 Liters to 60,000 Liters

- Offered in Stainless Steel 316, 304 or Carbon Steel material

- Spirals welded on outer surface of the main vessel for uniform circulation of heating or cooling media like steam, oil, water etc. And also provides extra strength to the main vessel

- Adheres to ASME and other standards with special attention to Argon and Arc welding procedures

- Save Energy using two part Jacket design for smaller batch

- GMP range of equipments available for Pharmaceutical industry. With mirror finish from 220 grit to 440 grit, smooth welding, flush grinding and Insulation with mirror finished S.S cladding

- Energy efficient direct drive design for the agitator , with VFD option to vary the RPM of the drive

- Agitator design to suit the reactants viscosity and density

- Vessel design with form cutter for the process which generates forms

- Save time and money with our Value added products and services like Process Automation, valves and fittings

- Manufactured as per your specifications

- Manufacturing facilities approved by the renowned consultants and Third party inspection agencies

Web Sales Agency

Web Sales Agency